I got my parts back from shaker. They look great. I painted the block a flat black rated to 2k° and oil resistant.

The crank and rod look real nice. This weekend I plan to check clearances so I can get everything put together so it isn’t sitting all over the garage.

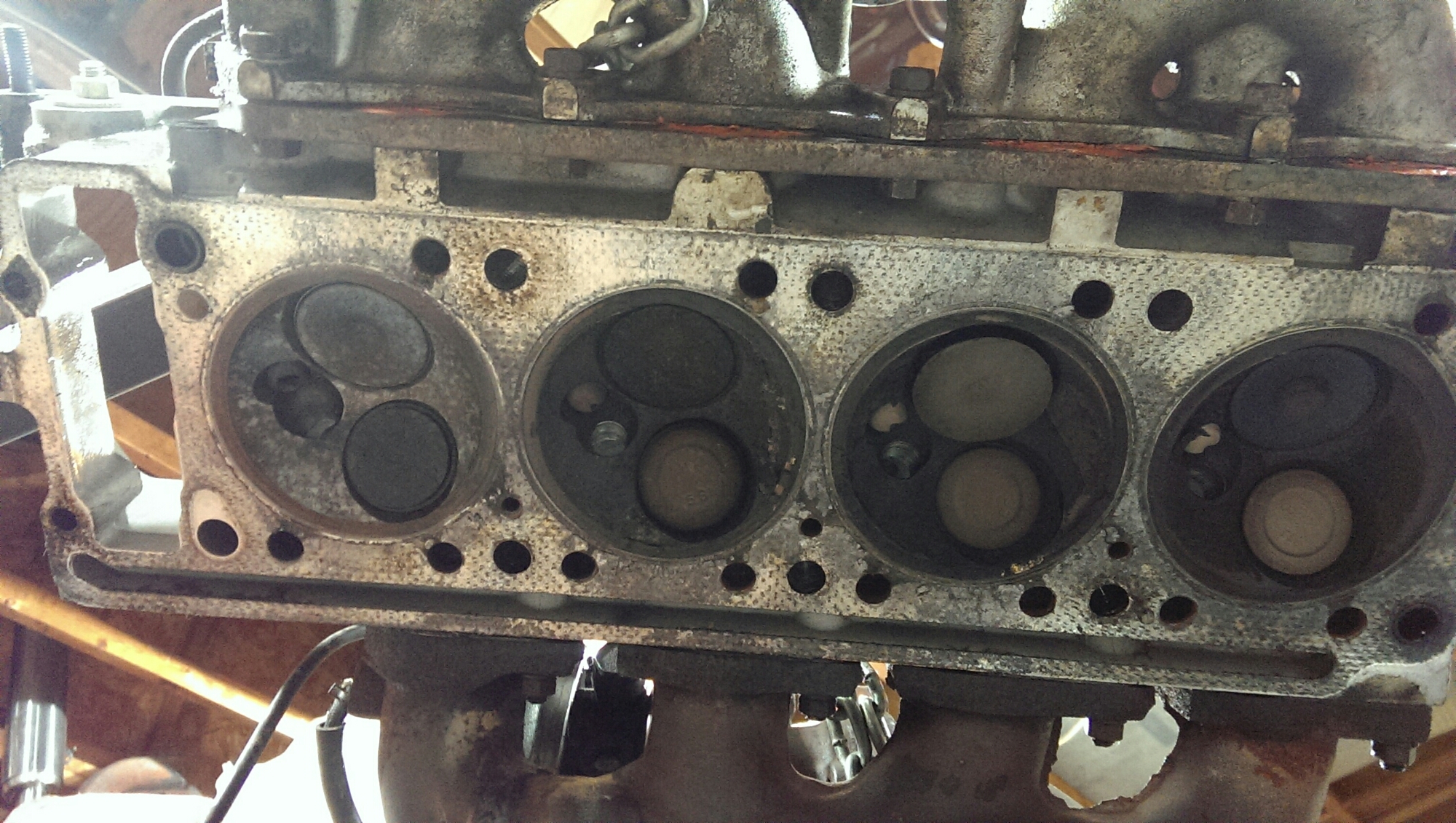

The head came out looking great. With 135lbs spring pressure. It might be able to push over 6k! Hah! Imagine that.

I also finally got a manual for this car. It’s filling in my blanks.